Coloring problems of PVC profile manufacturers

Therefore, in terms of PVC coloring, fully consider the characteristics of commonly used resins and related modifiers, and blend the characteristics of color paste. When selecting additives, we should pay attention to the following three problems:

1. Production and processing reliability

Some components in the additive will promote the dissolution of the resin. For example, iron ion and zinc ion are metal catalysts for PVC resin dissolution. Therefore, the use of compound (red, yellow, brown and black) pastes or reactive zinc oxide, zinc sulfide and lithopone type of milk color paste will reduce the heat resistance of PVC resin.

Some additives will react with the dissolved substances of PVC resin. If the alkali resistance of group blue paste is poor, then in the production process of PVC color, it will interact with the dissolved PVC hydrogen chloride, and lose the required color.

2. Mobility

Migration occurs only in plasticized PVC products, but also in the use of dyes or inorganic pigments. In other words, transportation is a part of soluble dye or organic pigment existing in the surrounding organic solvent. According to the tackifier penetrating into the surface of PVC products, these dissolved pigment particles are also sent to the surface of the product, which will form the degradation loss of gloss, organic solvent gloss loss or frost.

The other is "fouling.". It refers to that additives are dispersed from the production system due to the poor compatibility or incompatibility of the colorants in the coloring production process, and are accumulated on the surface of the production equipment (such as the inner cavity of the barrel and the inner cavity of the die hole of the extruder).

3. Weather resistance

It refers to the color paste to accept a variety of weather endurance ability. It includes visible light and ultraviolet light, moisture, temperature, air chlorination and organic chemicals encountered during the service life of the product. Important weather resistance, including the durability of non retreat, delamination resistance and process performance.

Organic pigments, on the other hand, have different structures. In addition, in the formula with milk color paste, the aging resistance of color paste will be relatively poor.

The discoloration, darkening or color change of color paste is generally caused by the reflection gene of color paste. This kind of reflective gene can work with water in the air or organic chemicals: acid and alkali.

For example, cadmium yellow can fade under the effect of moisture and sunlight. Lisol red has good light resistance and is suitable for most indoor applications, but it is more serious when used outdoors with acid and alkali.

Source: PVC profile manufacturer www.zhongshanlida.cn

-

12-17

Extrusion molding of plastic profile manufacturers

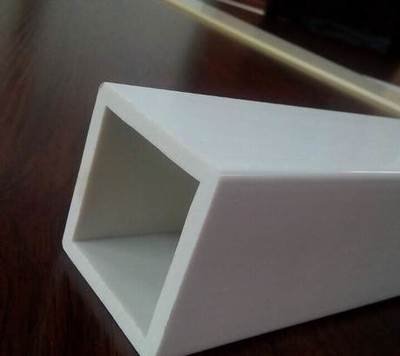

Plastic profile extrusion molding planning considerations. In the planning of extrusion molding of plastic profile, special attention should be paid to the uniformity of wall thickness, fillet and stiffener. If there is any omission, it will lead to irreparable defects. Li, chief engineer of the plastic molding Research Institute of Tsinghua University, also pointed out that the planning of plastic products is very different with different cooling and setting methods. Let's take a look at the th

-

12-17

Influence of technical commonness on PVC profile manufacturers

The coextrusion of PVC profiles and multicolored surface layers is one of the most popular coloration methods for PVC profiles in China. From 2002 to now, the development trend of producing colorful profiles by CO extrusion is rapid, accounting for about 40% of the sales market of colorful profiles, and it is estimated to reach 80% in 2020. By using coextrusion technology, the milky white PVC profile can be colored, and the aging resistance, temperature resistance and impact resistance of the PV

-

12-17

Coloring problems of PVC profile manufacturers

Therefore, in terms of PVC coloring, fully consider the characteristics of commonly used resins and related modifiers, and blend the characteristics of color paste. In the selection of additives, we should pay attention to the following three problems: 1. Production and processing reliability, some ingredients in additives will promote the dissolution of resin. For example, iron ion and zinc ion are metal catalysts for PVC resin dissolution. Therefore, the use of compound (red, yellow, brown and

-

12-17

Analysis on the defects of PVC profile manufacturer's production process

PVC profiles are widely used and bring convenience to our life. Generally, when we choose PVC profile, we will go to the regular business to buy, this posture quality is more guaranteed. We should read the operation manual carefully before using PVC profile, so that there will be no problem in the application process, which will affect our work. Some time, due to our improper use of methods will form PVC profile can not be used normally, then what should we do? 1. Surface tarnish: causes: poor p